GERLACH CABLE DIVISION

Welcome to the Cable Division website. As the leading provider for vulcanization technology, we offer you special solutions for production of siliconized and rubberized cables and wires.

With the perfect combination of hot air, infrared and microwave energy forms, we offer you innovative machine concepts for cost-effective and energy-saving production of your cables, wires and conductors.

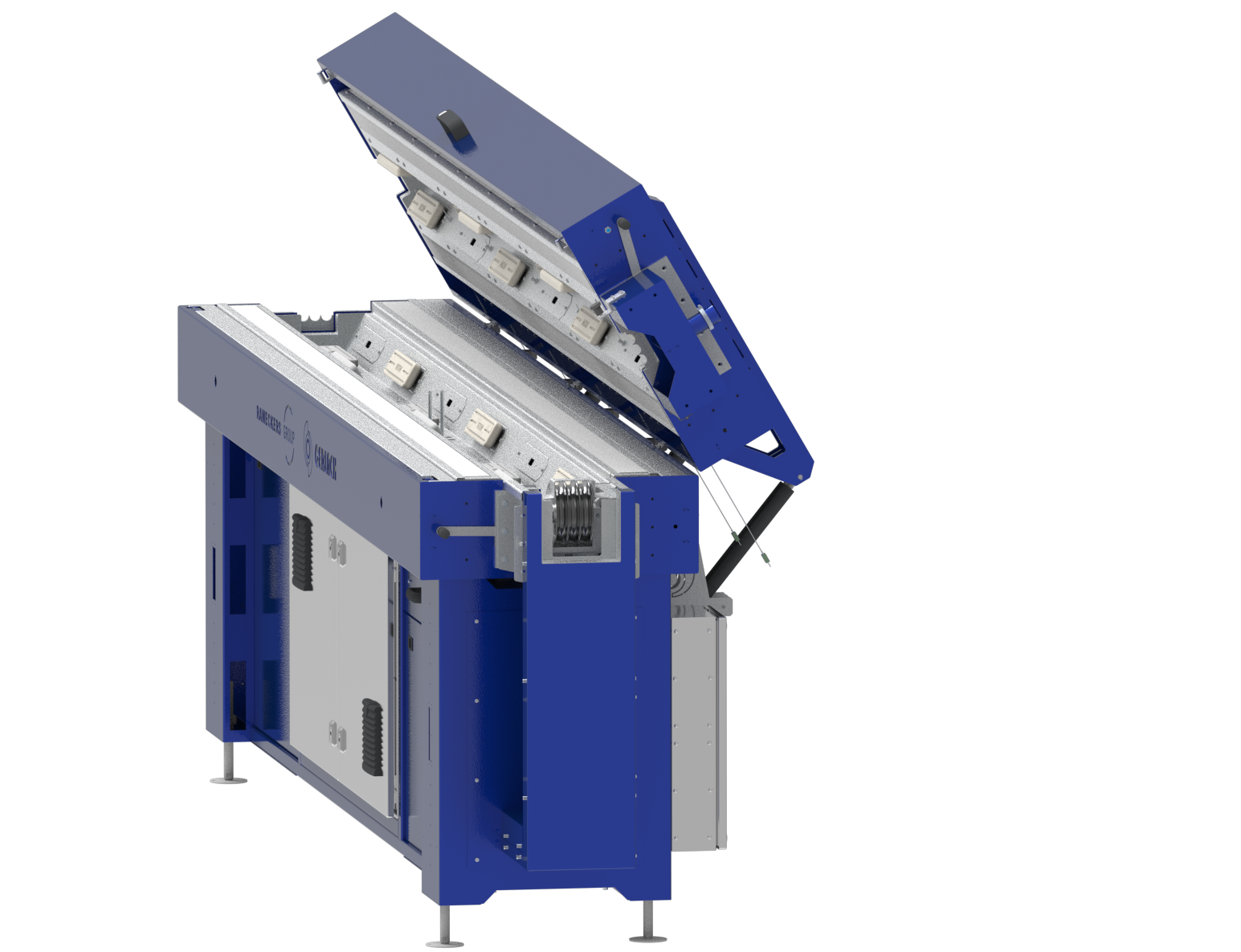

The modular machine series 300 relies on a targeted energy input into the sheath of your cable or conductor. A mix of the forms of energy hot air, infrared technology and microwave gives your product exactly the form of energy for an efficient cross-linking process of your elastomer cables.

The modular machine series 300 relies on a targeted energy input into the sheath of your cable or conductor. A mix of the forms of energy hot air, infrared technology and microwave gives your product exactly the form of energy for an efficient cross-linking process of your elastomer cables. With guided wave technology and the latest microwave technology, even siliconized cables can be processed. Thanks to the modular system concept, you always remain flexible in the selection of the system length, the types of energy used and the overall performance. By varying different energies, you achieve the flexibility you need for your product range.

Using microwave technology that is ideally tailored to the product range, we achieve crosslinking of the sheath material such as silicone or rubber. This leads to a faster crosslinking reaction with lower energy requirements at the same time. For you, this means faster production speeds while reducing energy costs.

You are interested in machine solutions for cable production. Then write us a short message indicating which products you produce or what challenges you have. We would be happy to provide you an individual system concept.

Always ready for use with our preventive maintenance concept. We would be happy to offer you a service concept tailored to your needs. Whether annual maintenance, preventive service or flat rates for services and parts. We have the right service model for every need.

You need a spare part. The fastest way to send your request to our Support.

Elastic profiles, mostly made of a rubber material, more and more also of silicone, are our daily companions, without us perceiving or even seeing them properly! But they play a key role in many applications: they seal windows and doors in our homes and cars, for example. They ensure that our environment remains comfortable, warm and dry. They are made of natural or synthetic rubber and must be vulcanized to be permanently elastic. Exactly this process is carried out in the vulcanization plants of GERLACH Maschinenbau.

Materials Week Europe from February 24 to 26 in Amsterdam

India Rubber Expo from April 7 to 10 in New Delhi

GPS 2026 from September 28 to 30 in Louisville, KY

Silicone Expo 2025 in Amsterdam, March 19 – 20

Global Polymer Summit 2025, USA, September 8 – 11

K 2025 in Düsseldorf, October 8 –15