Home » Products

A machine as flexible as your products. With the machine series 300 we are setting new standards in cable production. Flexible, energy-saving and innovative. The modules are available as Hot-Air, infrared or microwave units and can be arranged in any order. Depending on the product, exactly the energy sources that are required for the production of your product are used. Each module includes technological highlights. In the hot air modules, the temperature and the air flow rate can be regulated separately.

The particularly energy-saving operation in a 100% air recirculation principle is possible via an intelligent air recirculation control. Depending on the application, the infrared units are equipped with different light sources and wavelengths. Although microwave technology is widely used in elastomer technology, it is not widely used in the cable industry. The “guided wave” microwave system patented by Gerlach makes it possible for the first time to crosslink siliconized cables with the help of microwave radiation. This opens up new possibilities in terms of production speed, energy consumption and line lengths.

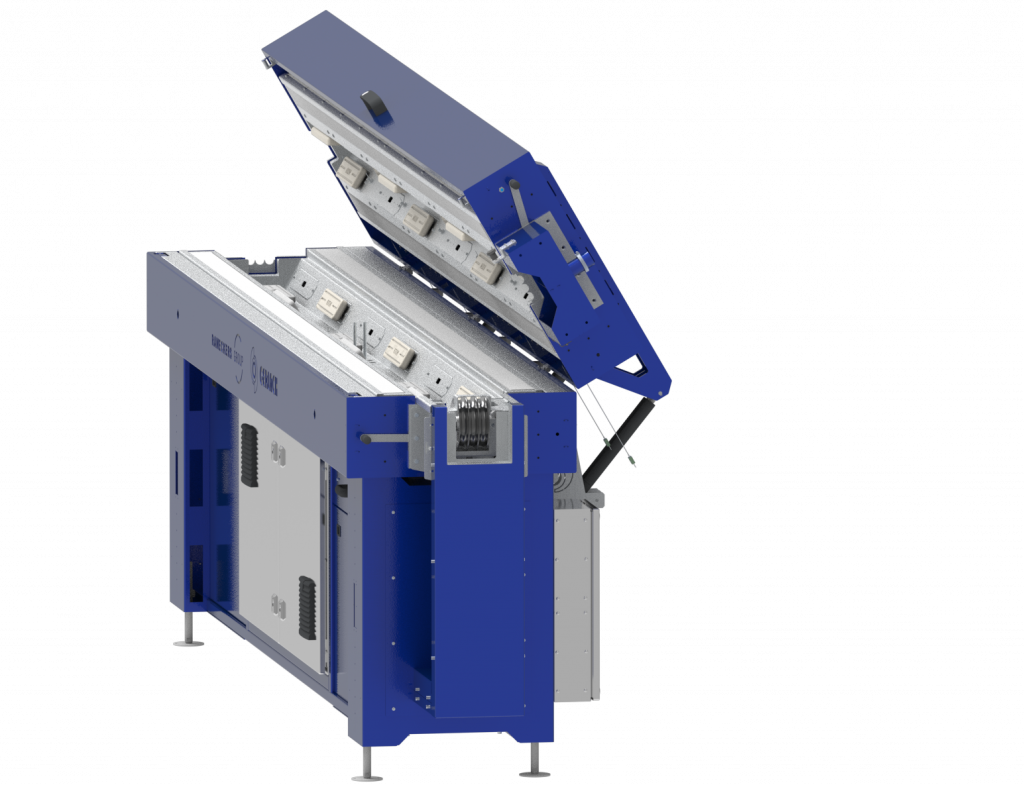

With the Hex 330 machine series, we offer a system concept for sintering PTFE-coated cables and conductors. Each module is 3m long and has 18 infrared heaters. The opening of the system has the dimensions 90×90 mm. A special screen allows the opening to be reduced to a minimum after set-up. The spotlights are mounted in an alternating hexagon to eliminate shading when processing several cables or wires at the same time. At the inlet and outlet of the system there is a roll holder for holding 3 cables. The system only needs to be opened for maintenance purposes. The set-up process takes place with the lid closed. To do this, the cables are attached to a pull-in aid that pulls the lines through the system when the cover is closed.