Close

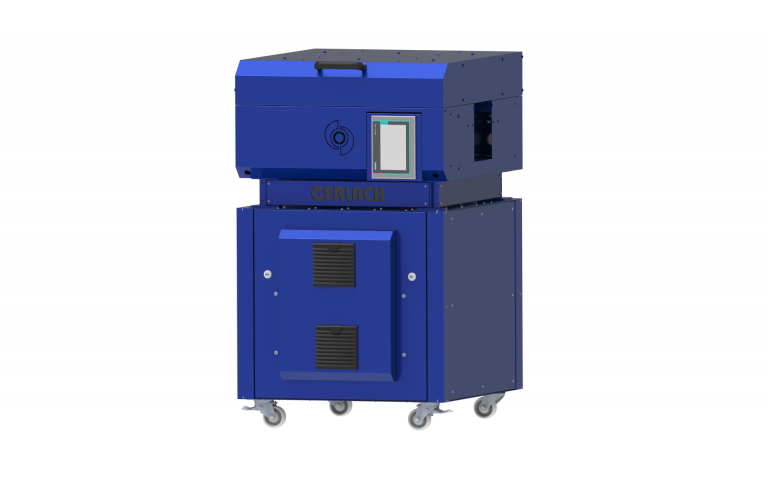

The modular machine series 300 relies on a targeted energy input into the sheath of your cable or conductor. A mix of the forms of energy hot air, infrared technology and microwave gives your product exactly the form of energy for an efficient cross-linking process of your elastomer cables.

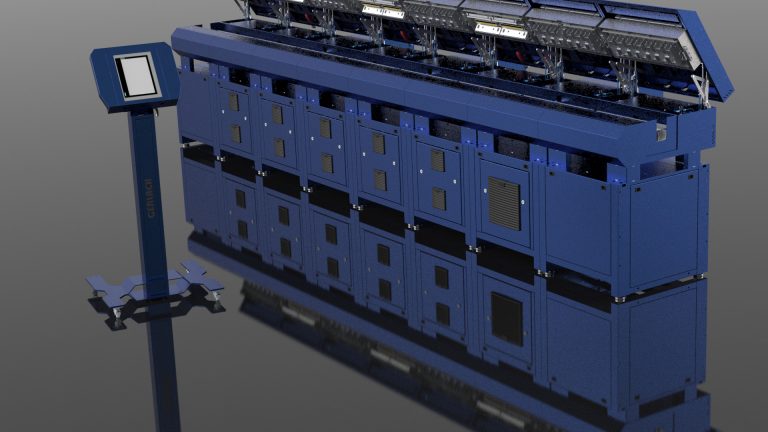

With guided wave technology and the latest microwave technology, even siliconized cables can be processed. Thanks to the modular system concept, you always remain flexible in the selection of the system length, the types of energy used and the overall performance. By varying different energies, you achieve the flexibility you need for your product range.

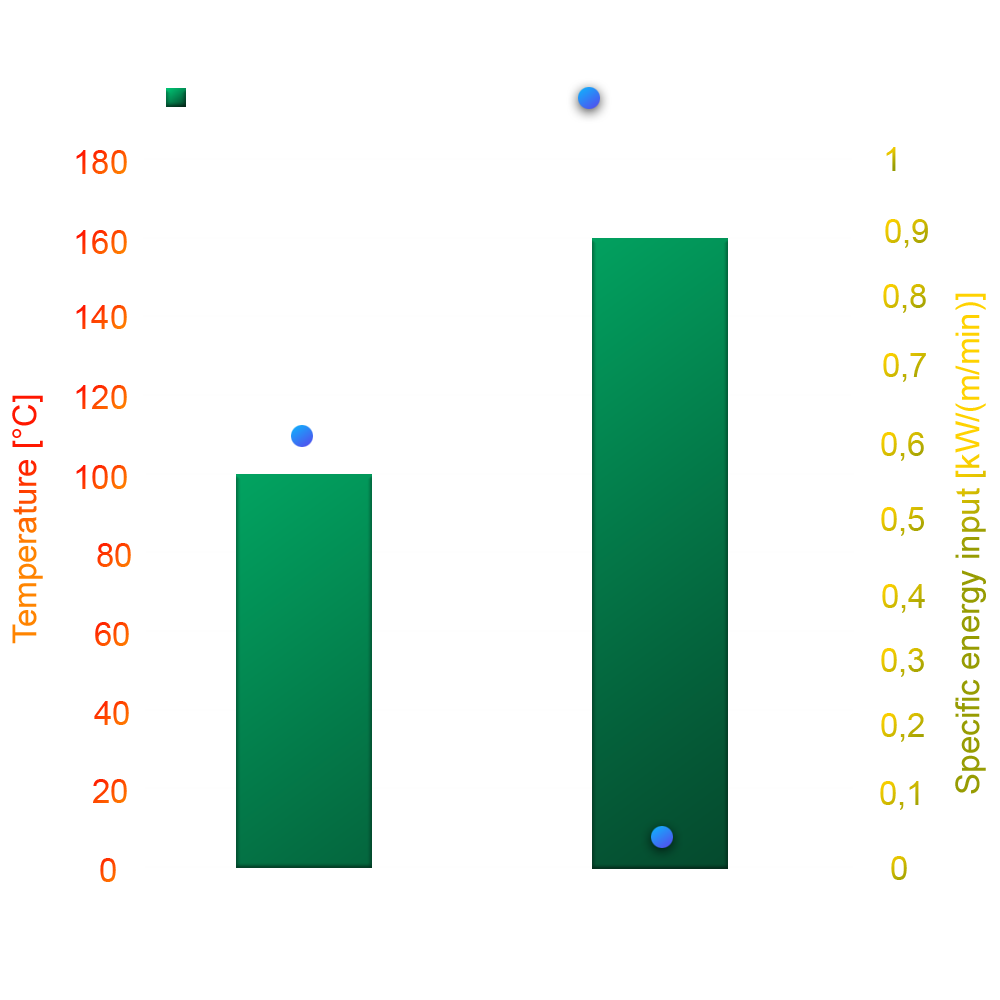

Adjust the machine to your process. Give the product exactly the amount of energy and the form of energy that is optimal in the process. By mixing different forms of energy and intensities, you not only produce in a way that conserves resources and saves energy, but also faster and more efficiently. The latest microwave technology offers you completely new possibilities to rethink your processes.

When Gerlach talks about being environmentally friendly, we’re not talking about saving 10 or 20% of energy. Even during the production of our systems, we pay attention to environmental standards and produce ourselves with 100% green electricity. The special thing about the system concept is the completely new and revised energy supply. Self-cleaning circulating air systems and targeted heat input via electromagnetic radiation are setting new standards in the crosslinking of elastomers. So far it has not been possible to network conductor-based cables with microwave radiation.

Thanks to the guided wave technology from the Gerlach company, even siliconized cables can be networked in addition to classic rubberized cables. Due to the flexible and modular system concept, the system can be flexibly adapted to your production program. 2 systems become one, or one system becomes 2. Depending on the configuration and energy mix, it is always precisely tailored to the upcoming production program. We would be happy to explain how this works in a personal meeting.

What is the right form of energy. How long does the product need to be supplied with energy until the networking process is complete. What are the ideal operating parameters. What is the ideal batch size for efficient and resource-saving production. Frequently asked questions that are not so easy to answer.

With the new modular machine concept, you can adapt your production specifically to your needs and production parameters. Do not heat any unnecessary machine components, bring exactly the energy to your product that is relevant for the desired result. An optionally available energy and heat absorption monitoring gives you full control over your process. Together with our experts, you will develop new production strategies and reduce your CO2 footprint. Knew how!

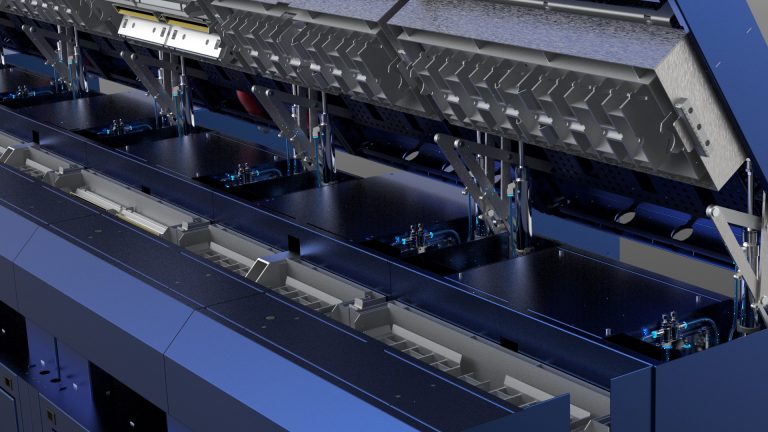

The machine concept is based on a modular design with different forms of energy. Each module can be exchanged with each other and the system can be variably expanded or shortened. There are currently 3 different module types available. The hot air module, the infrared module and the microwave module.

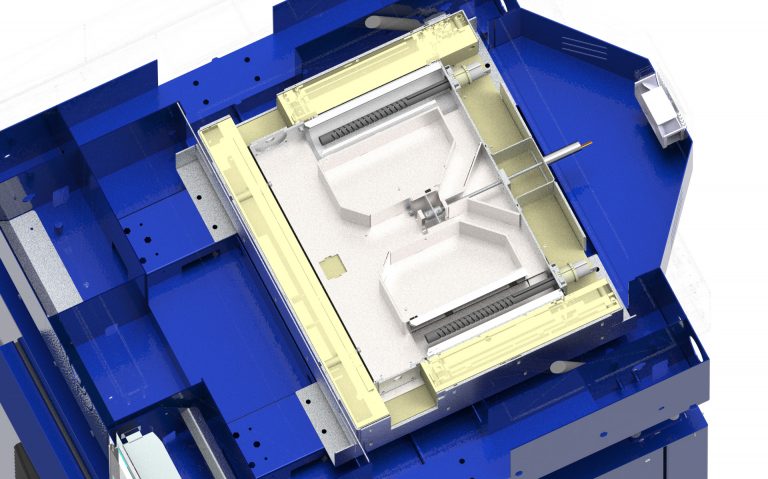

The hot air module offers a heating cassette in which the temperature and the flow rate can be controlled independently of each other. Even temperature-sensitive products can absorb a lot of thermal energy due to high flow speeds. Other products, on the other hand, expect high heat with only little convection. Due to the specially developed self-cleaning circulating air flow, operation in 100% circulating air mode is possible. Due to the low fresh air exchange, 2 KW connection power is already sufficient to reach temperatures of up to 500°C.

Not only new, but unique in the networking of cables, we offer microwave technology for the networking of elastomeric cables. The guided wave technology allows the targeted energy input even into products that were previously said not to be heated with microwaves. Since microwave technology does not result in any losses through transfer heat, this form of energy supply is particularly effective. Compared to classic infrared processes, the energy consumption of the microwave is often less than 50%. Special absorbers ensure that the process is not only efficient, but also safe. We would be happy to explain how this works in detail in a personal meeting.