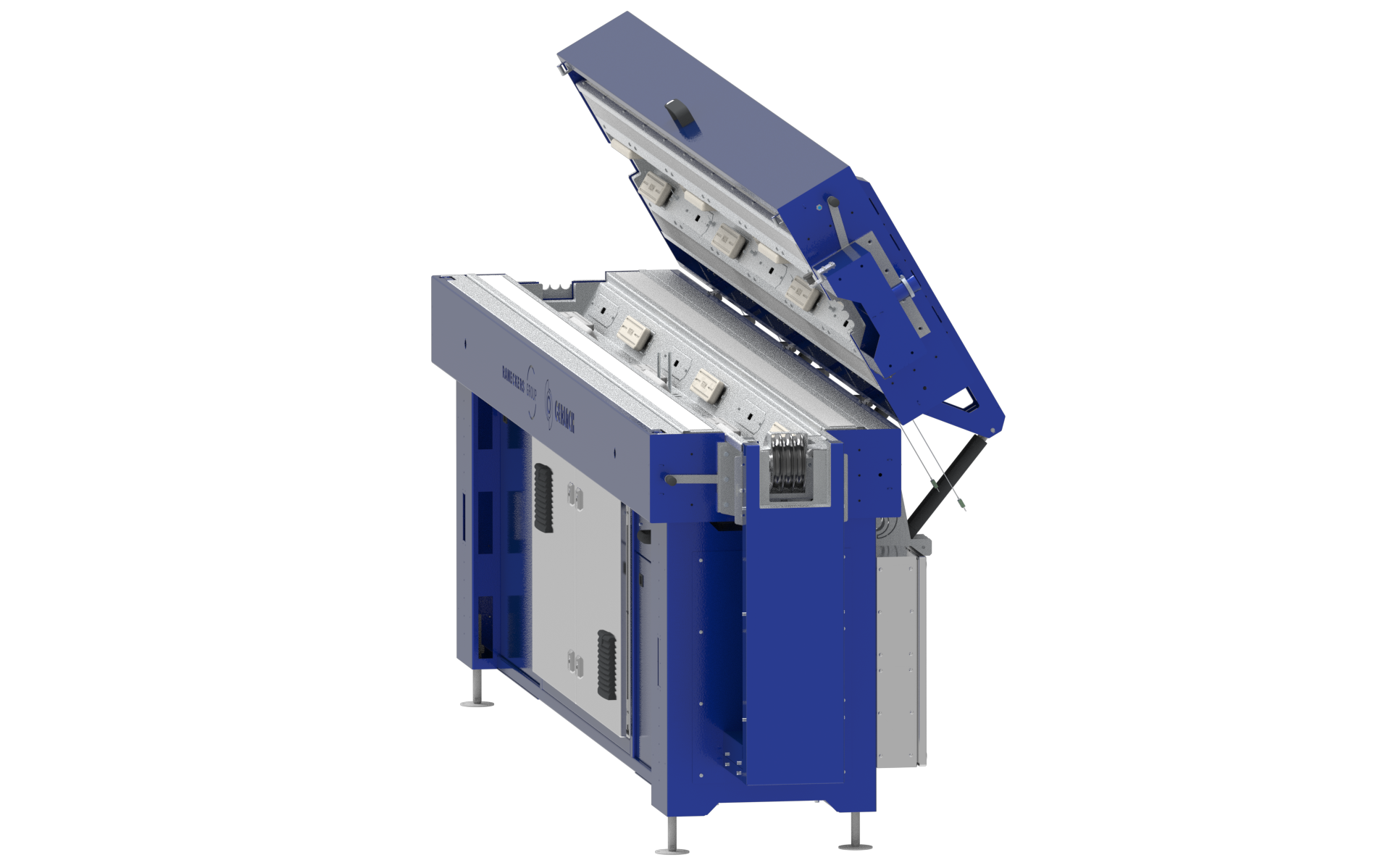

With the Hex 330 machine series, we offer a system concept for sintering PTFE-coated cables and conductors. Each module is 3m long and has 18 infrared heaters. The opening of the system has the dimensions 90×90 mm. A special screen allows the opening to be reduced to a minimum after set-up. The spotlights are mounted in an alternating hexagon to eliminate shading when processing several cables or wires at the same time.

At the inlet and outlet of the system there is a roll holder for holding 3 cables. The system only needs to be opened for maintenance purposes. The set-up process takes place with the lid closed. To do this, the cables are attached to a pull-in aid that pulls the lines through the system when the cover is closed.

The sintering of banded PTFE cables requires a high degree of temperature stability. With the PTFE Hex 300 we offer a system technology that is optimized precisely for this application. The hexagonal arrangement of the infrared radiators allows the simultaneous processing of up to 3 cables.

When Gerlach talks about being environmentally friendly, we’re not talking about saving 10 or 20% of energy. Even during the production of our systems, we pay attention to environmental standards and produce ourselves with 100% green electricity.

The special thing about the system concept is the completely new and revised energy supply. Optimized thermal insulation and control technology specially developed for the application reduce the energy requirement and also offer a stable process.

The machine concept is based on a modular design with different forms of energy. Each module can be exchanged with each other and the system can be variably expanded or shortened. There are currently 3 different module types available. The hot air module, the infrared module and the microwave module.

The sintered PTFE cable is cooled down in the cooling channel before further processing. This 3m cooling segment has its own cooling water supply, which can be regulated using a heat exchanger. The system offers the possibility to process 3 strands at the same time. The applied cooling water is blown off at the end of the cooling basin with energy-saving mini air blowers. Each blower can be controlled individually.